Introduction to Fogging and Related Terminology

The article introduces readers to fogging, a term widely used since the 1920s to describe the process of fumigation or gas delivery for disinfection purposes. It explores various techniques and equipment associated with fogging, including traditional spray machines, warm foggers, and cold foggers. Each method is examined in terms of its efficacy, droplet size, and suitability for different environments, such as agricultural settings or enclosed spaces with humans or animals. The article also raises questions about the practical application of fogging devices in herd productivity enhancement and highlights the need for better communication between equipment manufacturers and disinfectant producers to optimize results.

Fogging Process

The term "Fumigation" has been used since around 1920 to refer to the process of fogging or gas delivery. This method involves using toxic substances in the form of gas to disinfect or eliminate disease-causing agents, insects, etc.

Fogging is particularly popular in veterinary medicine, where formaldehyde gas is generated by heating formaldehyde to its boiling point or reacting it with an oxidizing agent like potassium permanganate at specific ratios.

This method is widely used for eliminating fungi in fruit storage warehouses, with initial university research conducted in agricultural industries for gasification in this area. In fumigation, gas is generated by heating the desired substance and bringing it to its boiling point.

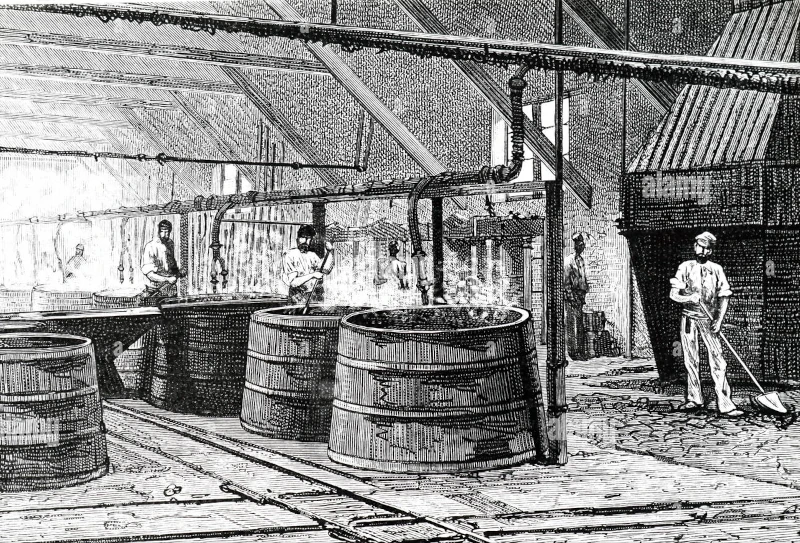

Fogging is performed using fogging machines. Essentially, these machines convert the solution from their outlet into ultra-low volume particles or very fine droplets and release them. These devices, mainly used for disinfection or pesticide spraying, create droplets so fine that the volume of the solution resembles fog to the human eye, with droplet sizes ranging from 5 to 50 microns. Research has shown that droplets of disinfectant or pesticide in this size range are highly effective in eliminating various pathogens and insects. Moreover, formulations with concentrations ranging from 10 to 90 percent of the pesticide or disinfectant with water or oil can be prepared in these machines. The flow rate of droplets exiting the nozzles of the device is 30 liters per hour.

Traditional High-Pressure Spray Machines or Backpack Sprayers

These devices produce relatively larger droplets, around 100 to 200 microns. These droplets do not cover the entire surface well, resulting in less impact on parasites. Besides producing large droplets, these devices also consume more time and energy during operation. Although traditional motorized sprayers do not have this problem, they are not very suitable for indoor use as they make the environment very wet and damp. Additionally, when fossil fuels are used, exhaust gas emissions in enclosed spaces are undesirable.

Warm Foggers

In this method, disinfectants or toxins are heated and released as visible vapor or dense fog. The droplet size is about 10 microns. Warm fogging is ideal for applying large quantities of disinfectants or poisons. Due to the exhaust gas generated by the device, this method is not suitable for enclosed environments with humans or animals.

Cold Foggers

This method operates by pressurizing the disinfectant or toxin solution so that the pressurized solution collides with special nozzles and powdered particles, creating fine droplets (ultra-fine particles). Because these foggers use electrical power, they do not have exhaust gas issues and are very suitable for enclosed environments.

Conclusion

Fogging, nebulization, and fumigation methods, which can be translated as gasification, spraying, and fogging, respectively, share a common feature: they all create the solution in the form of fine droplets or a form that has a better effect than its initial state on the target surface. It seems that currently in Iran, especially in the veterinary industries, the term "fogging" brings to mind humidity-generating devices. However, why devices with these specifications do not actually find practical application in the application of disinfectants to create a better impact on herd productivity?

The answer to this question can be attributed to the lack of information from fogging machine manufacturers or disinfectant manufacturers in providing methods compatible with indigenous fogging devices or humidity generators.